Ntau tus neeg tsis paub txog chlorinated polyethylene, thiab raws li lub npe qhia, cov neeg feem coob tsuas yog tuaj yeem pom tias nws yog cov khoom siv tshuaj. Nws muaj cov txheej txheem hu ua extrusion molding, uas tseem tseem ceeb heev hauv cov txheej txheem ntau lawm. Yog li niaj hnub no, peb yuav tsum xyuam xim rau dab tsi thaum lub sij hawm extrusion molding txheej txheem ntawm cov khoom no? Chlorinated polyvinyl chloride

1. Nyob rau hauv cov ntaub ntawv raw cov ntaub ntawv rau kev tsim cov kav dej, yuav tsum tau them nyiaj mloog mus rau kev xaiv ntawm stabilizers thiab lwm yam kev pab, nrog rau lub ntsiab tseem ceeb ntawm kev txhim kho cov yaj fluidity thiab txhim khu lub thermal stability ntawm raw cov ntaub ntawv. Yog tias tsim nyog, cov ntaub ntawv formula tuaj yeem sib xyaw ua ntej, thiab cov qauv me me tuaj yeem raug coj mus kuaj. Yog tias tsis muaj qhov tshwm sim tsis pom tseeb lossis qhov tshwm sim decomposition nyob rau hauv 230 ℃ muab lub thawv rau 2 teev, nws qhia tau hais tias kev xaiv cov khoom siv yog tsim nyog.

2. Cov txheej txheem extrusion molding kub ntawm chlorinated polyvinyl chloride cov ntaub ntawv yog me ntsis siab dua li ntawm cov kav dej PVC. Tab sis nws yuav tsum tau muab sau tseg tias qhov ntsuas kub tswj qhov hloov pauv tsis tuaj yeem tshaj ± 5 ℃.

3. Thaum lub sij hawm tsim cov kav dej CPVC, yog tias muaj hluav taws xob, cov khoom siv tsis ua haujlwm, cov cim qhia ntawm cov khoom tawg, lossis cov pa luam yeeb tawm ntawm lub qhov ncauj pwm, cov khoom siv rau lub tshuab chim yuav tsum nres tam sim ntawd. PVC resin yuav tsum tau siv los tshem tawm CPVC cov khoom siv melting ntawm lub tshuab chim thiab pwm, thiab tom qab ntawd lub tshuab yuav tsum raug tso tseg kom daws teeb meem.

4. Ua ntej cov resin muab tso rau hauv ntau lawm, nws yuav tsum tau qhuav thiab kho nyob rau hauv ib tug 80 ℃ mov thawv rau 2-4 teev. Yog tias tsim nyog, cov khoom siv high-speed sib xyaw yuav tsum tau ua los ntawm 40 mesh sieve ib zaug, thiab tom qab ntawd muab tso rau hauv extruder hopper rau ntau lawm.

5. Cov roj HCl tso tawm thaum lub sij hawm decomposition ntawm CPVC yaj yog teeb meem rau tib neeg noj qab haus huv, thiab yuav tsum tau them nyiaj mloog mus rau qhov cua nyob rau hauv lub rhiav ntau lawm.

6. Lub tshuab extrusion chim, ntsia hlau, thiab cov khoom molten ntws los ntawm cov pwm molding siv los ua CPVC resin yuav tsum tau kho los tiv thaiv corrosion kom ntev lub neej ntawm cov khoom siv.

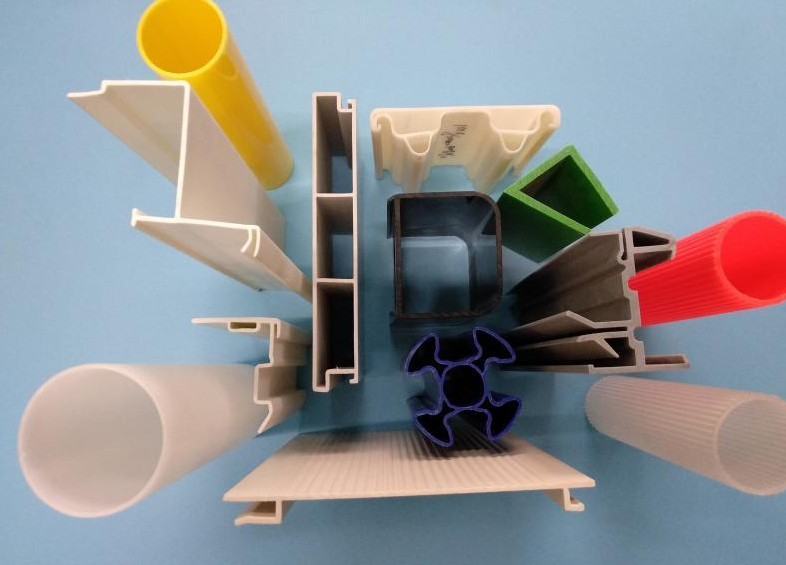

Hauv cov txheej txheem tsim khoom tiag tiag, cov txheej txheem extrusion molding ntawm chlorinated polyvinyl chloride tseem nyuaj heev. Tau kawg, nws yog ib qho tseem ceeb uas yuav tau xaiv cov khoom tsim nyog thaum siv nws hauv qee lub sijhawm, thiab peb yuav tsum ua tib zoo xav txog qhov ntau npaum li cas ntawm cov khoom kom pab txhawb kev siv tau zoo dua.

Post lub sij hawm: Nov-16-2023